AI‑Powered Smart Manufacturing

AI‑Powered Quality Inspection & Yield‑Improvement Solution – achieving over 98% accuracy to help manufacturers reduce costs, improve quality, and boost efficiency.

Request a DemoSolution Value

Core Modules

AI Defect Detection & Classification System (ADC)

AI Model Training Platform

Yield Analysis & Management System (YMES)

Intelligent Command Center / Monitoring Dashboard

Intelligent Automated Equipment (AI Camera)

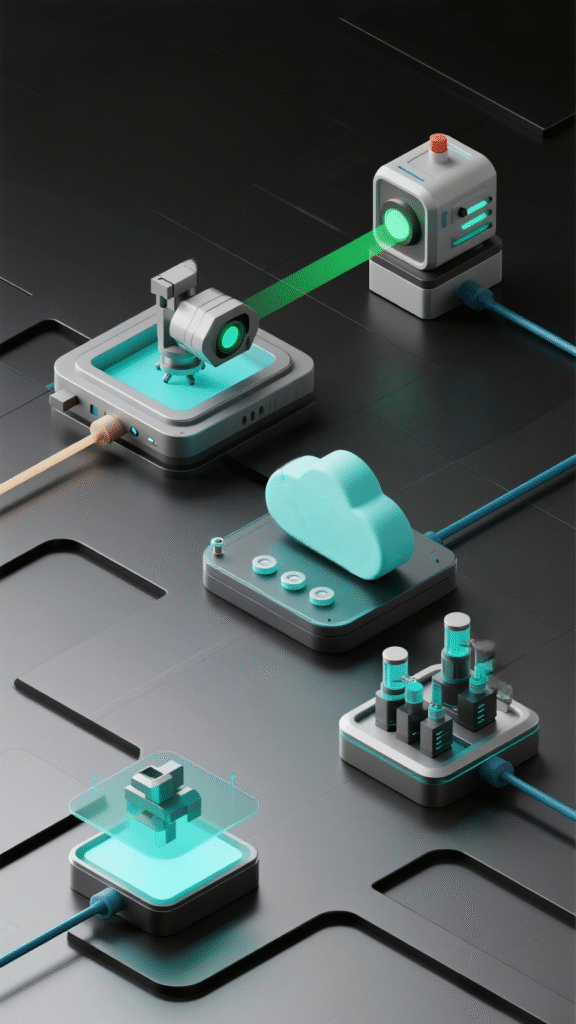

Overall Architecture

Device End (RDI)

Edge Side

Central Cloud

Key Advantages

High Precision & Efficiency

Full‑Stack Technology Coverage

Flexible & Rapid Deployment

Proven Reliability

Quantified Benefits

-

Performance Highlights

-

Over 10 billion images processed by AI; equipment stable operation exceeding 1 million hours.

-

Average inspection efficiency improved 10-fold, directly reducing labor costs by over 50%.

-

Effectively lowers the risk of quality incidents, reducing customer complaints and return losses.

-

Application Scenarios

-

Automotive Industry

Provided complete‑vehicle compliance and anti‑miss‑assembly inspection of components for a top domestic joint‑venture automaker. Using a machine‑vision system, it automatically verifies the correctness of vehicle option configurations with 100% coverage and a system recognition accuracy ≥8%, eliminating installation errors and omissions. -

Advanced Display Industry

Replaced manual inspection for TV‑set appearance, diffuser plates, and other stages for a globally leading display manufacturer. Successfully reduced missed‑detection rates to <0.5% and over‑detection rates to ≤5%, achieving labor substitution while significantly improving the stability and consistency of quality checks. -

Metal Packaging Industry

Deployed an AI‑based color‑print appearance inspection system for a comprehensive packaging‑solution provider with revenues in the tens of billions. Through high‑speed flying image capture and a proprietary deep‑learning framework, it enables millisecond‑level defect identification and automatic material rejection, accurately detecting complex defects such as missing print, scratches, and contamination—keeping quality risks firmly under control on the production line.