When AI Conducts “Scientific Research” in Industry: FundeAI’s AI4S Practice

In 2024, the Nobel Prize in Chemistry was awarded to AI-driven protein structure prediction technology, marking the moment when AI for Science (AI4S) formally moved from the frontier of academic research to the center of industrial innovation. From the State Council’s Guiding Opinions on Deepening the “AI+” Initiative, which places “AI + Science and Technology” at the top of national priorities, to dedicated policies launched by Beijing and Shanghai to accelerate implementation, AI4S has become a core engine for reshaping scientific paradigms and activating industrial innovation.

According to GF Securities, the global AI4S market is expected to exceed USD 500 billion by 2027, with China—supported by a complete industrial chain and rich data resources—potentially capturing 40% of the market share. As a digital-intelligence transformation service provider, FundeAI anchors itself in industrial demand and advances AI4S from laboratory research to large-scale industrial application through a three-dimensional path of “technology foundation, scenario implementation, and ecosystem collaboration,” ensuring that scientific discovery is truly transformed into productivity.

The Scientific Revolution Triggered by AI4S

The 2024 Nobel Prize list provided authoritative confirmation of a long-brewing scientific revolution.

The Chemistry Prize honored scientists who fundamentally solved the protein structure prediction problem through the AI system AlphaFold, while the Physics Prize recognized pioneers of neural networks who laid the foundations of modern deep learning.

Together, these awards point to a single, unmistakable trend: the deep integration of artificial intelligence and scientific research has become an irreversible paradigm shift.

This is more than a simple upgrade of tools. Experts from the Chinese Academy of Science and Technology for Development note that AI4S represents an entirely new research paradigm. It begins with massive datasets, uses machine learning to first discover “what happens,” and then works backward to explain “why it happens,” overturning the traditional research logic of “hypothesis first, verification later.”

In basic research, AlphaFold3 has compressed protein structure prediction cycles from decades to mere days, while Huawei’s Pangu meteorological model enables second-level global weather forecasting—demonstrating AI’s extraordinary ability to handle complex scientific problems.

On the industrial side, AI4S has already delivered breakthroughs in materials science, drug discovery, and energy optimization. NVIDIA’s BioNeMo platform has shortened new drug development cycles from five years to one year while reducing costs by 90%. ZT New Materials used AI-driven atomic-level simulations to increase aluminum alloy strength by 22%, successfully deploying the technology in Saudi Arabia’s NEOM project.

Yet industrial-grade AI4S adoption is not a simple matter of technology transfer. It faces three fundamental challenges:

-

Data silos limit access to high-quality training samples, while the specialization and complexity of scientific data raise governance barriers.

-

Misalignment between technology and industrial needs, as most AI4S tools are designed for research environments rather than large-scale industrial deployment.

-

A shortage of hybrid talent—professionals who understand both AI algorithms and domain-specific scientific principles remain extremely scarce.

These challenges define precisely where FundeAI positions its industrial AI4S efforts.

FundeAI: A Practical Path for Industrial-Grade AI4S

Driving this scientific revolution requires four indispensable elements. Authoritative analyses consistently identify the success of AI4S as resting on the integrated foundation of data, computing power, algorithms, and security.

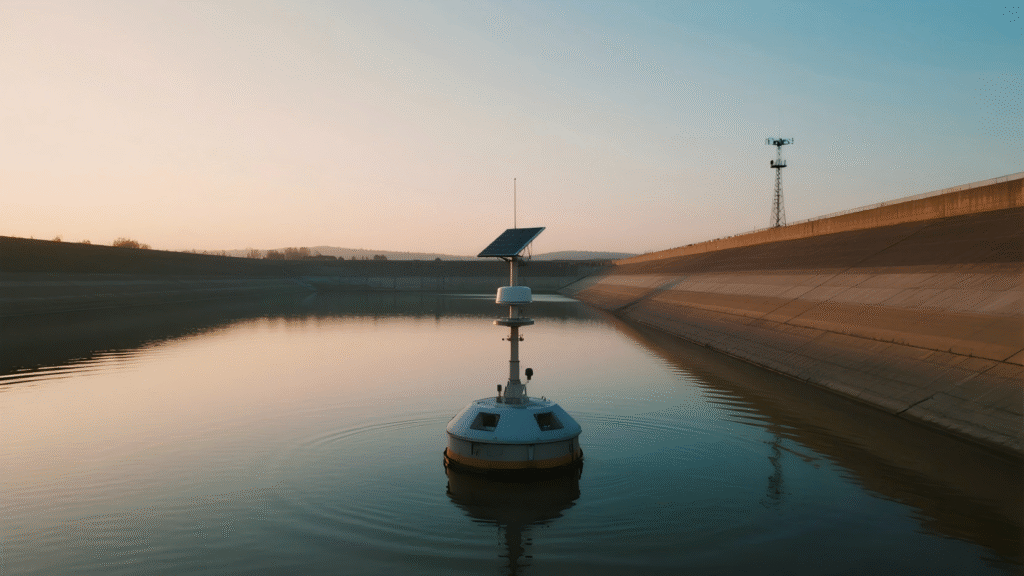

Data is the raw material of AI4S. High-quality, multimodal datasets form the basis for training and optimization. Unlike laboratories constrained by limited samples and dimensions, industrial environments naturally generate continuous, closed-loop, high-value data at scale.

Computing power is the productive force of AI4S. Training complex deep-learning models and processing massive datasets demand robust high-performance computing engines.

Algorithms are the tools of AI4S production, determining how valuable information is extracted from data and transformed into predictions and decisions.

Security is the foundation of trust. In industrial applications, data assets, model intellectual property, and system stability are mission-critical. Security is no longer optional—it is the prerequisite for compliant data circulation, protection against model attacks, stable system operation, and safeguarding core business secrets. It is the fundamental guarantee for large-scale AI4S deployment.

Equally critical—though often implicit—is domain expertise. True industrial AI4S cannot succeed without deep understanding of industry-specific know-how.

This is precisely the wave FundeAI has chosen to ride: introducing the AI4S paradigm deep into industrial contexts.

Unlike laboratory research that seeks fundamental laws of the universe or life, industrial AI4S focuses on discovering optimal solutions and hidden patterns within complex, constraint-laden, efficiency-driven commercial systems.

In the field of health management, FundeAI’s work goes far beyond basic data analytics. In collaboration with ecosystem partners, it has built a full-lifecycle management system spanning prevention, screening, diagnosis, treatment, and rehabilitation. Leveraging dynamic ontology technology, FundeAI extracts and correlates health risk factors from multi-source behavioral data to construct professional risk variable libraries. This effectively enables continuous knowledge discovery and relationship mining within complex life-and-health data networks, supporting precise risk control and dynamic pricing.

In energy and chemical industries, FundeAI combines AI and data capabilities with partners’ deep domain expertise to target core production processes. Through models such as raw-material formulation optimization and safety-production early warnings, the system autonomously searches for safe, efficient, and low-carbon optimal production pathways within massive solution spaces defined by composition, temperature, pressure, and energy consumption.

This is akin to installing a tireless “chief scientist” within chemical plants, continuously running virtual experiments and intelligent optimization.

In financial services and urban governance, FundeAI applies its Wuzhen foundation model and Zhuque data platform to real-time monitoring, simulation, and early warning across macroeconomic trends, corporate credit, and public safety.

In effect, this constructs a “simulator” and “detector” for social and economic systems, designed to uncover latent risks and emerging opportunities from massive, dynamic interaction data.

Across these diverse practices lies a single core logic: using a self-controlled technological foundation of data, algorithms, computing power, and security as the engine, and leveraging high-value, closed-loop scenarios in finance, health, energy, and governance within the FundeAI ecosystem as experimental fields and data sources—systematically tackling long-standing industrial challenges that are invisible, poorly understood, hard to measure, and difficult to control.

Paradigm Shift Eastward: The Next Stop for AI4S Is Deep Industrial Integration

The AI4S wave is rapidly moving from the world’s top laboratories to the front lines of industrial application.

In China, leading institutions are building systematic layouts. The Shanghai AI Laboratory has open-sourced the Intern scientific discovery platform, hosting more than 200 interdisciplinary intelligent agents and opening petabyte-scale authoritative scientific datasets—aiming to create “revolutionary tools.”

Meanwhile, pioneering enterprises are applying AI’s scientific discovery capabilities to concrete industrial challenges.

Chinese research teams have used large language models to analyze tens of thousands of academic papers, narrowing catalyst screening from tens of millions of combinations to just hundreds of candidates. Combined with automated experimentation, this approach has compressed development cycles that might otherwise span thousands of years.

In the petrochemical industry, leading enterprises have built digital-twin factories, using AI algorithms to deeply optimize production scheduling, quality traceability, and market pricing—reducing changeover losses by 40% and shortening pricing response times by 75%.

Together, these cases reveal a clear truth: AI4S derives its vitality from deep integration with complex industrial scenarios, where its value multiplies through efficiency gains, R&D breakthroughs, and the creation of entirely new possibilities.

As AI becomes a “super brain” for scientific discovery, competition in industrial AI4S will shift from isolated technological breakthroughs to comprehensive capabilities spanning technology, scenarios, and ecosystems.

FundeAI’s push into industrial AI4S is not built on empty ground. It is underpinned by a unique foundation of group-level strategy and a diversified ecosystem.

Trillion-scale ecosystem scenarios provide high-quality data fuel. AI4S is highly dependent on data quality. The FundeAI ecosystem spans finance and insurance, health management, energy and chemicals, and property services—industries that naturally generate massive volumes of real, closed-loop, high-value, continuously growing data. This constitutes a rare and precious “data ore” for training industrial intelligence models.

A dual-track computing strategy delivers a powerful production engine. To overcome potential computing bottlenecks, FundeAI has built a dual-track model combining cutting-edge NVIDIA exploration with domestic deployment, embracing global innovation while securing autonomous and controllable computing foundations.

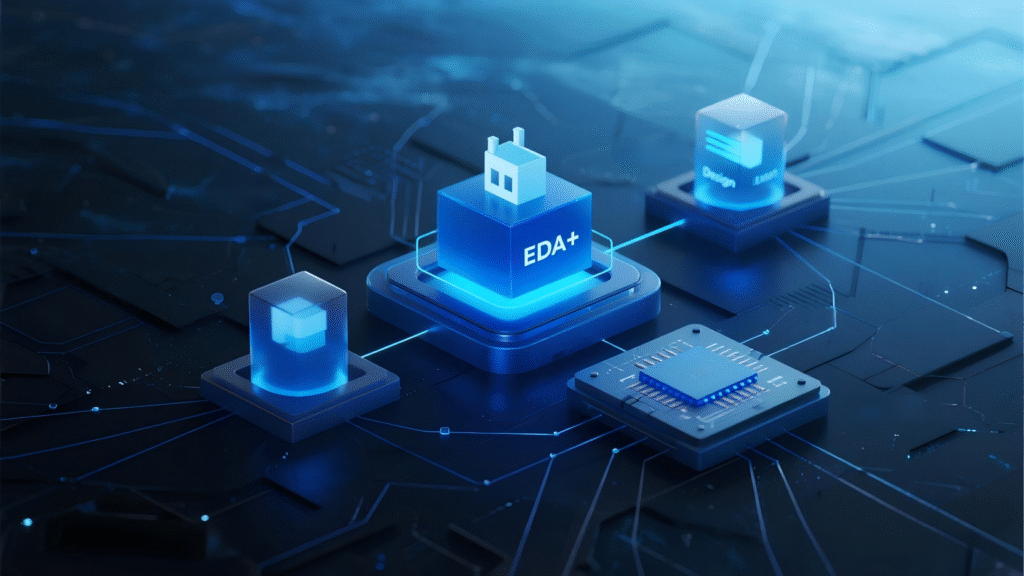

Eight core technology foundations form a self-reliant toolbox. From the Wuzhen foundation model and Zhuque data platform to the Tianzhu security system and Kunlun dynamic ontology, FundeAI’s eight independently developed technology pillars provide a full-stack toolchain for industrial AI4S—from data governance and knowledge construction to model training and security protection.

From niche exploration in research labs to mass innovation in industry, AI4S is unleashing an unprecedented productivity revolution. Staying true to its mission of “empowering industrial upgrading through digital intelligence,” FundeAI is bringing AI4S out of the ivory tower and into real production environments—turning it into a powerful engine for enterprise innovation and industrial transformation, and writing a distinctly Chinese answer at the intersection of technological revolution and industrial change.