Chemical, Mining & Energy Products

Overcoming High Energy Consumption, High Risk, and Low Efficiency

Expected Outcomes & Value

Core Capabilities & Advantages

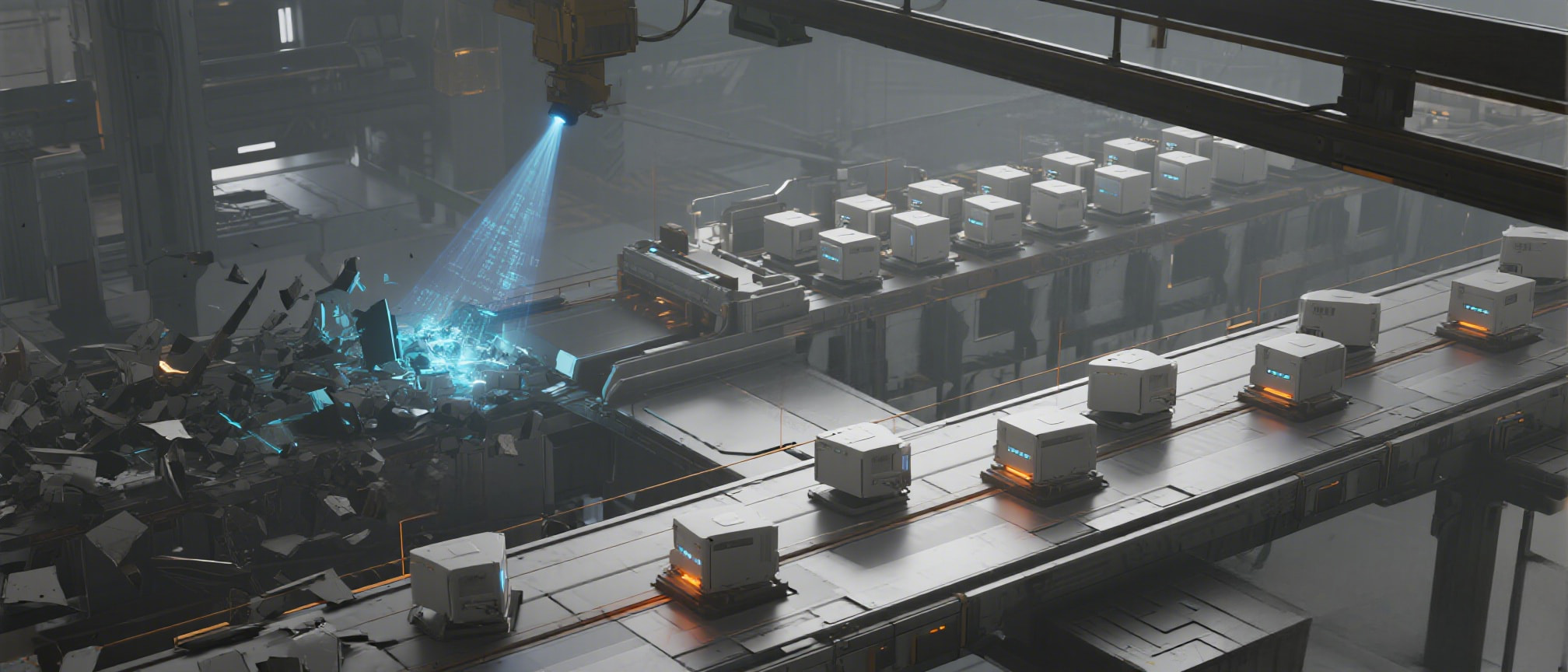

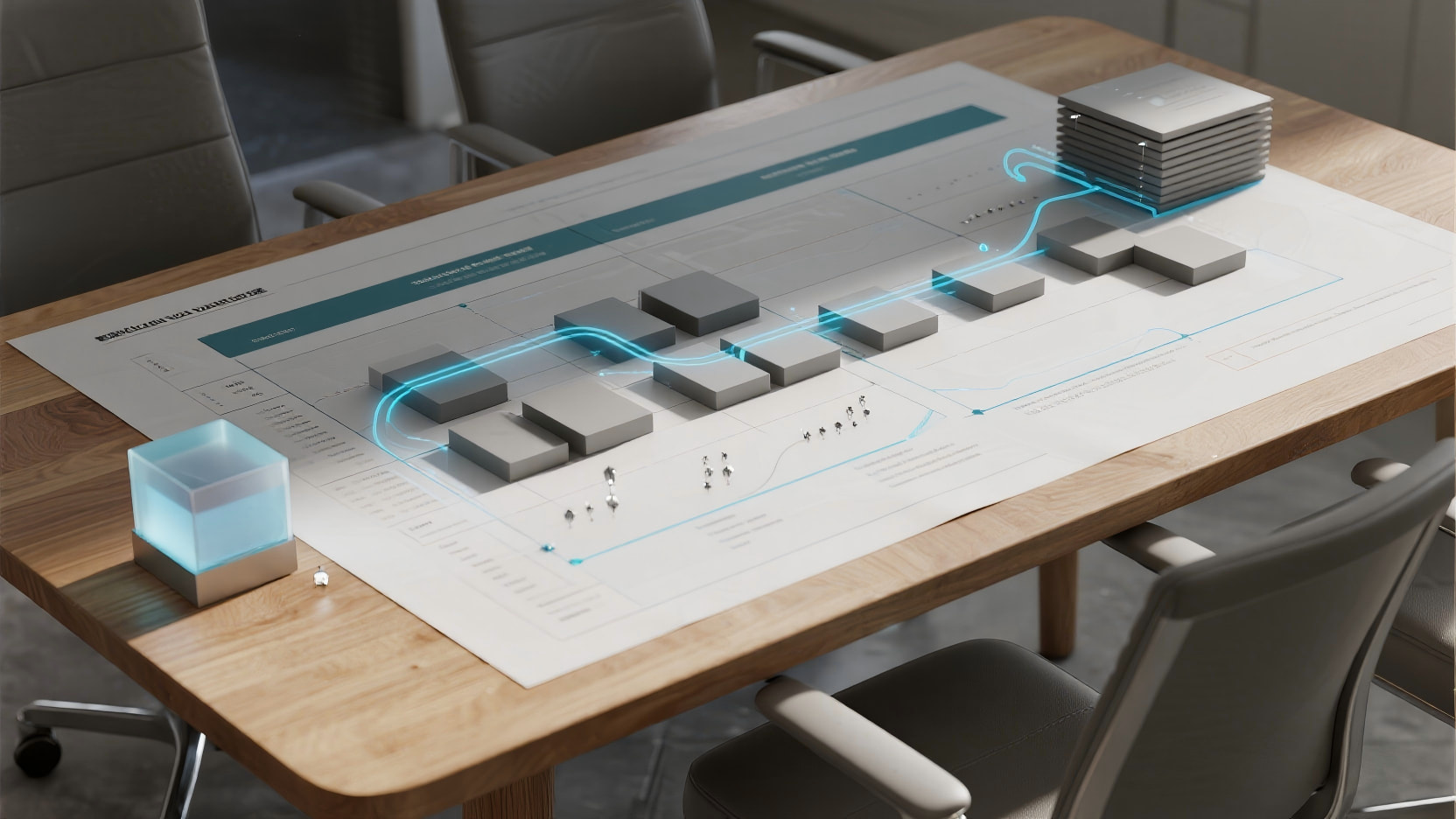

Intelligent Production Optimization System

Built on an industrial internet platform, this system creates a smart optimization framework covering the entire production process. It collects real-time equipment operation data, process parameters, and energy consumption metrics, using AI algorithms to establish multi-objective optimization models for automatic process adjustment and refinement. The system dynamically tunes production parameters based on raw material properties, equipment status, and environmental factors, maximizing capacity utilization and minimizing energy consumption while ensuring product quality.

Smart Production Safety Monitoring Platform

This platform establishes a comprehensive safety risk perception and early-warning system. Deploying a network of intelligent sensors, it monitors hazardous source conditions in real time. Combined with intelligent video analytics, it provides full oversight of personnel behavior, equipment operation, and environmental safety. Utilizing risk assessment models, it automatically identifies potential hazards, distributes tiered alerts, and offers emergency command decision support, significantly elevating corporate safety management.

Supply Chain Collaboration & Optimization System

An end-to-end digital supply chain management platform integrates data from supplier management, inventory control, and logistics. It employs big data analytics to accurately forecast market demand and intelligently formulate production plans and inventory strategies. An EDI (Electronic Data Interchange) platform enables efficient collaboration with suppliers, optimizing resource allocation, reducing operational costs, and accelerating market response.

Equipment Health & Energy Efficiency Management Platform

This platform innovatively combines equipment management with energy efficiency optimization. A predictive maintenance model forecasts potential equipment failures and intelligently schedules maintenance. Simultaneously, it creates a comprehensive energy consumption overview for granular efficiency management. By analyzing data to identify optimization opportunities, it provides continuous energy-saving improvement strategies, achieving dual enhancement of equipment reliability and energy efficiency.